欢迎您访问湖北联鸿能源科技有限公司网站,我司主营汽车蓄电池配件、工业蓄电池维护保养产品

全国咨询热线:0710-3313598

Technology

TechnologyA team led by the University of Glasgow (UOG) has created a new type of lithium battery using 3D printing technology using plant starch and carbon nanotubes as electrode materials, it was reported on March 22. This would provide greener, higher-capacity power for mobile devices. The findings are in the Journal of Power Sources.

Lithium-ion batteries are lightweight, compact and have good cycle performance, making them ideal for powering laptops, mobile phones, smartwatches and electric cars. Lithium-ion batteries contain a positive electrode made of lithium cobalt, manganese oxide or lithium iron phosphate, and a negative electrode made of lithium metal. During the charging process, lithium ions flow from the positive electrode to the negative electrode through the electrolyte. During the discharge process, ions flow in the opposite direction, generating energy through an electrochemical reaction that powers the device.

Electrode thickness is one of the main physical factors affecting the energy storage and release of lithium-ion batteries. The thick electrode will not only limit the diffusion effect of lithium ions on the electrode, thus limiting the specific energy of lithium-ion battery, but also reduce the strain tolerance of the battery, making it more prone to failure due to cracking.

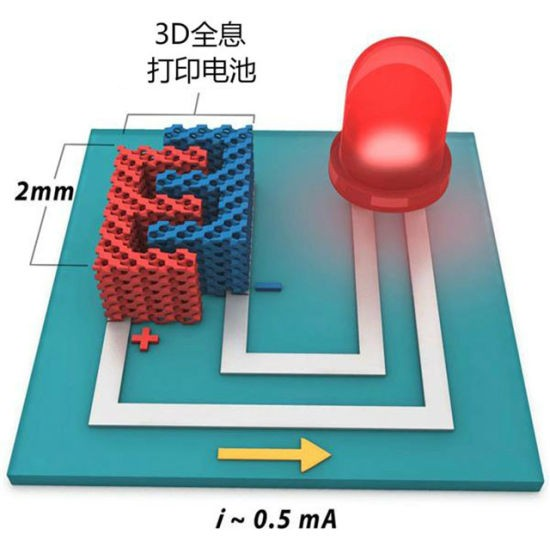

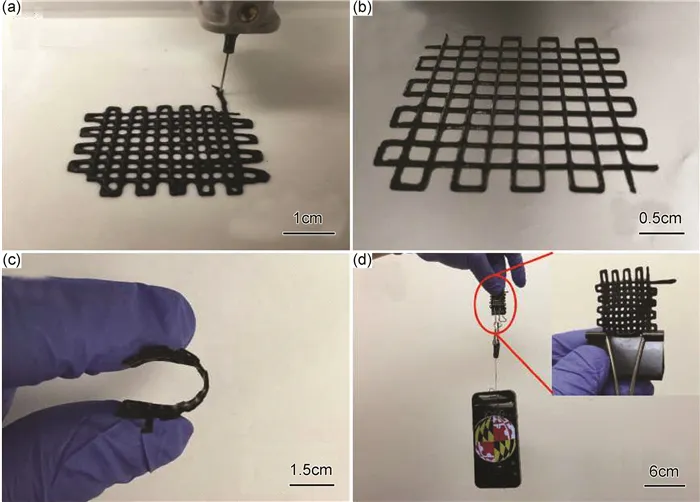

UOG's cells aim to create a better balance between electrode size and surface area by introducing nanoscale micropores. Compared with solid electrodes of the same external size, the surface area of the microporous electrode is significantly increased. To do this, the researchers used 3D printing, or additive manufacturing, to precisely control the size and position of the microholes in the electrodes. The main raw materials for 3D printing are polylactic acid, lithium-iron phosphate and carbon nanotubes. Among them, polylactic acid (PLA) is a biodegradable material processed from corn starch, sugarcane starch and beet starch, which effectively improves the recyclability of batteries.

The researchers tested the performance of circular electrodes with different thicknesses (100, 200 and 300 microns) and different material combinations (carbon nanotubes containing 3 to 10 percent) with different microporosity (10 to 70 percent). The results show that the electrode with a thickness of 300 microns and a microporosity of 70% has the best performance, with a ratio of 151mAh·g-1, which is about 2 to 3 times the capacity of traditional lithium-ion batteries with solid electrodes of the same thickness. This optimization method also solves the problem caused by electrode thickness. Compared with the 100-micron thick electrode, the 300-micron thick electrode increased its storage capacity by 158%.

Author and project leader Dr ShanmugamKumar said: "Lithium-ion batteries have become an important part of everyday life. With the development of electrification and sustainability, its importance will continue to grow. However, the sustainability of lithium-ion batteries cannot be ignored. In this study, we used a 3D printing process to precisely control the microporosity of the electrodes, which to some extent makes up for the shortcomings of existing lithium-ion batteries. We hope to continue to explore the potential applications of this micro-structured electrode material to develop recyclable lithium batteries with superior performance and ease of recovery."