欢迎您访问湖北联鸿能源科技有限公司网站,我司主营汽车蓄电池配件、工业蓄电池维护保养产品

全国咨询热线:0710-3313598

Technology

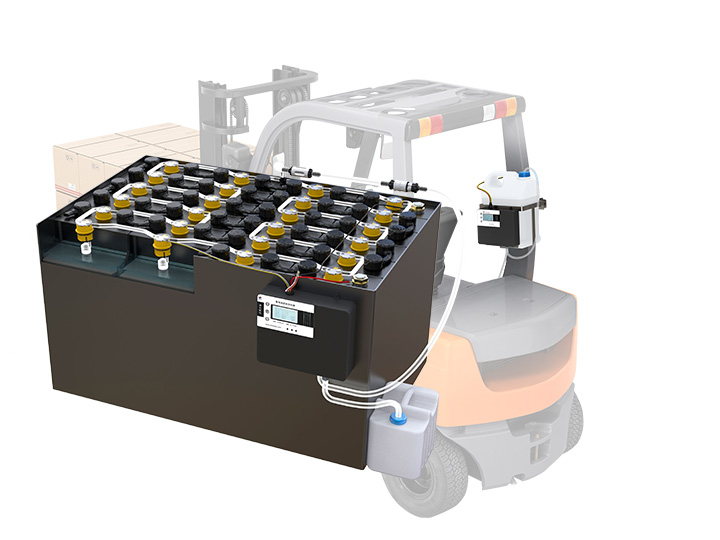

TechnologyElectric forklift battery water replenishment system is an automatic water adding device, which can solve the water adding imbalance, leakage, and more, etc. In the use of electric forklift battery, water replenishment is a necessary step, but also more tedious, a little careless, easy to lead to errors.

Electric forklift battery automatic water adding system is a mature technology and practical system, very easy to use. Battery add water, all the filler plug from the buoy concatenated together, and in the water at the same time, has been filled with fluid jacking buoy in the monomer, sealed unit into the hole, at the top of the whole unit plug buoy up after the charging process is completed, in the process of charging and discharging, due to the electrolytic and evaporation, lead to the water in the electrolyte will be reduced gradually, so as to make the electrolysis drawdown. The water replenishing system developed by Yujie Power supply is easy to operate. After charging, you only need to plug in the quick connector and stop automatically after adding water. If the general battery is not replenished in time, it may shorten the service life of the battery. The supplemented water should be distilled water, and should not be replaced by pure drinking water, because the pure water contains a variety of trace elements, which will cause adverse effects on the forklift battery.

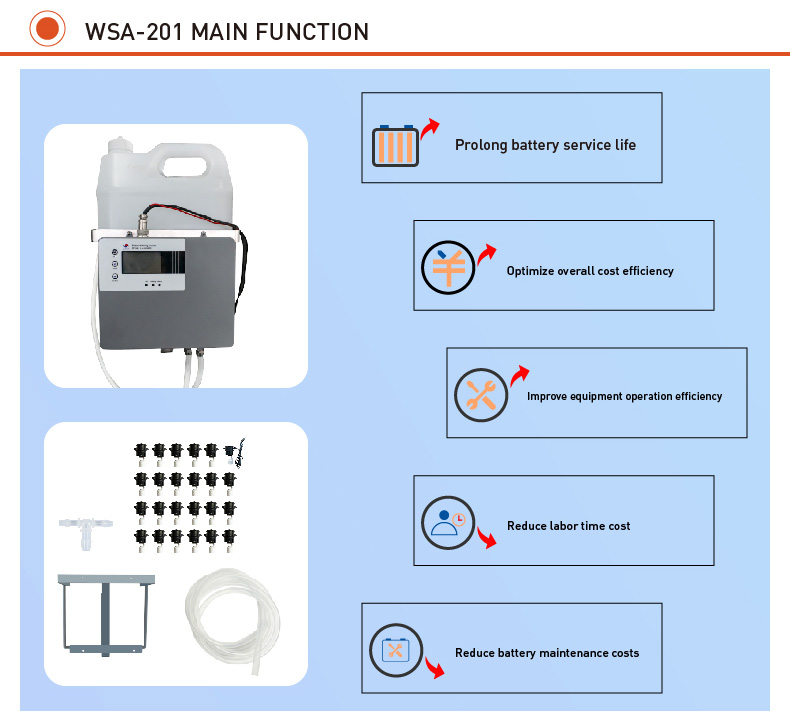

Electric forklift battery filling water system is the company independent research and development of patented products, is a battery development in view of the rich fluid automatic filling equipment, can fully replace the artificial water battery maintenance operations, real-time monitoring of battery and dehydration, automatic filling water, with water induction automatic stop, after the installation of equipment can keep the electrolyte level the entire in health, to ensure that the battery electrolyte features stable, Balance, optimize the efficiency of storage battery equipment, prolong the service life of storage battery. For more detailed instructions on the use of the product, please contact our staff to communicate and provide you with professional technical guidance.

After receiving the battery, read the manual and the warning label on the outside of the battery box carefully before installing the battery. Familiarize yourself with the manual and warning label, which helps you use the battery efficiently and maintain the battery correctly, thus extending the battery life.

At present, the market is mainly divided into three kinds of liquid injection caps: ordinary basket type liquid injection caps, buoy type liquid injection caps and automatic water injection caps. Different water injection caps have different water adding methods and liquid level standards. The water adding methods and liquid level standards of batteries are as follows:

1. If the battery liquid level is lower than the lowest liquid level, add pure or distilled water to the range between the highest and lowest liquid level; Do not add battery stock solution or tap water; Do not add too much water beyond the highest level!

2. Time to add water: add water before charging period (one hour before the end of charging). Do not add water to the battery during use.

3. Principle of adding water: a small amount for many times, do not add too much water.

The above is the standard water adding method. If the liquid level is abnormal in accordance with the standard water adding method, please contact the manufacturer and add water under the professional guidance of the manufacturer.

By the end of 2018, domestic electric forklift ownership has reached 600000 units, of which more than 96% of the vehicles are used lead-acid batteries, lead-acid battery need daily distilled water add and maintenance, because of lack of lead-acid battery maintenance and management of some users, lead-acid battery without timely and effective accurate filling distilled water, which can produce high temperature of battery, Plate oxidation and other battery failure, battery performance attenuation and lead to its low efficiency, and then affect the performance of forklift itself.