欢迎您访问湖北联鸿能源科技有限公司网站,我司主营汽车蓄电池配件、工业蓄电池维护保养产品

全国咨询热线:0710-3313598

Technology

TechnologyElectric sightseeing vehicles are widely used in the city, and the battery is an important part of it. The battery still needs regular maintenance. How to operate the water supply of the battery is the following small edition to give you a detailed introduction.

Electric sightseeing vehicle battery water supply how to operate?

1. During battery use, water will be naturally lost, which will lead to the drop in liquid level. In this case, it is necessary to periodically unscrew the liquid hole cover and check the liquid level in each cell of the battery. At this time, of course, relevant precautions should be made clear. In any case, make sure that the plate inside the battery is completely covered by the liquid level, as dehydration can greatly shorten the life of the battery.

2. Normally, the environment used, the higher the temperature, the more frequently the battery is used, and the longer the time used, the faster the loss of water. Therefore, in the process of daily use, the liquid level should be tested. Different seasons, the corresponding inspection cycle will be different.

3. Use distilled or deionized water dedicated for batteries. Do not use tap water or river water. Of course at this time, also want to clear the relevant matters needing attention. Normally, high levels of impurity ions in the water can damage batteries. And when adding water, the liquid level height should be determined, not too much. In a word, in the battery refill water, it should be a comprehensive consideration.

4. Do not refill the battery until it is fully charged. If the surface of the plate is exposed before charging, add an appropriate amount of pure water to cover the plate, and then add the liquid level to the specified height after charging.

5. Determine the liquid level: Add water to the position 3-4mm below the bottom of the liquid level indicator (the plastic part deep into the battery inside the liquid injection hole).

Note: Do not add too much water, the liquid level should not touch the bottom of the liquid hole plug, so as to avoid acid overflow battery!

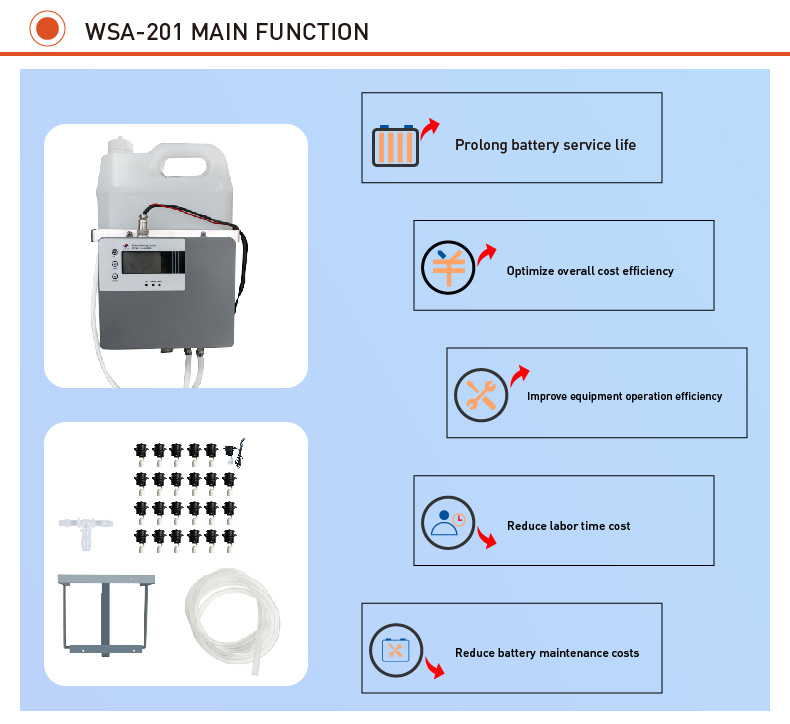

General lead-acid battery theoretically designed service life is 4-5 years, and the current market common service life of lead-acid battery is 1-3 years, in fact, nearly 80% of lead-acid battery service life is not more than 2 years, the use of efficiency is only about 40% of the theoretical value, Complicated maintenance of lead-acid battery, especially the omission and delay of water maintenance, is the main reason that the theoretical efficiency of the battery cannot be fully played.

Correct water replenishment method for battery of electric sightseeing vehicle

The operation and maintenance cost of traditional lead-acid batteries mainly includes daily water adding, cleaning and maintenance, and fault repair. The traditional manual water adding maintenance also needs to bear the labor cost and risk cost, such as personnel turnover, individual skill difference, staff training, and time cost. Once the water is added, the battery will die of thirst or the battery life will decrease, which will increase the battery operation and maintenance cost sharply.

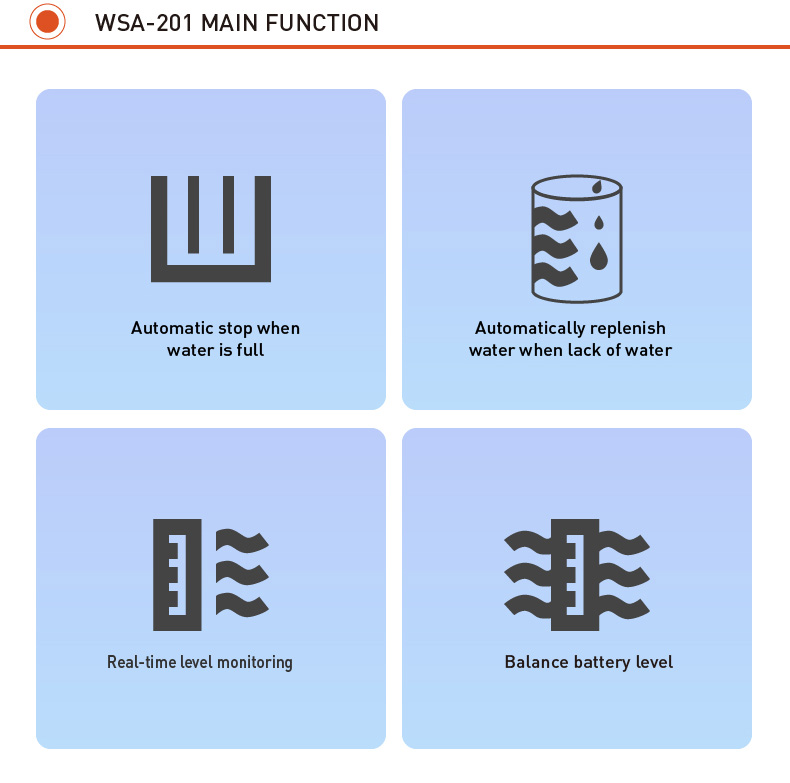

Battery intelligent water system is the company independent research and development of patented products, is a battery development in view of the rich fluid automatic filling equipment, can fully replace the artificial water battery maintenance operations, real-time monitoring of battery and dehydration, automatic filling water, with water induction automatic stop, after the installation of equipment can keep the electrolyte level the entire in health, to ensure that the battery electrolyte features stable, balance, Optimize the efficiency of storage battery equipment and extend the service life of storage battery.

Battery intelligent water adding system features

Automation: subvert the traditional manual and semi-automatic mode, automatic water replenishment

Intelligent: intelligent water shortage monitoring, intelligent water supply control

Integration: Integrated installation without additional connections or transfers

Equalization: Unified level control to ensure consistent battery unit characteristics

More efficient: 5 minutes to complete a water cycle

Safer: completely isolate the electrolyte from the operator

More reliable: completely eliminate the manual, semi-automatic water maintenance unreliability

Lham intelligent water feeder retains the advantages of high stability, strong environmental adaptability and low price of ordinary lead-acid battery, and has a stable service life and great maintenance convenience at a very low cost, with a very considerable cost performance.