欢迎您访问湖北联鸿能源科技有限公司网站,我司主营汽车蓄电池配件、工业蓄电池维护保养产品

全国咨询热线:0710-3313598

Technology

TechnologyForklift, as an important member of industrial handling vehicles, plays an irreplaceable role in many fields such as manufacturing, logistics, agriculture and construction with its strong carrying capacity and precise operational performance. This paper will give a detailed introduction to the classification, application scenarios and daily maintenance of forklifts.

1.The classification of forklifts

Forklifts can usually be divided into three categories: internal combustion forklifts, electric forklifts and storage forklifts. Due to the convenience of fuel supply, the internal combustion forklift can achieve long-term continuous operation, competent for harsh environment work, including ordinary internal combustion forklift, heavy forklift, container forklift and side forklift. The electric forklift is powered by the motor, the battery is the energy, the noise is low, and it is widely used in indoor operations and other conditions with high environmental requirements, such as medicine, food and other industries. The warehouse forklift is mainly designed for cargo handling in the warehouse.

2.The application scenario of forklift

Manufacturing: In the manufacturing industry, forklifts undertake the main handling tasks from the warehousing and storage of raw materials, to the material handling in the production process, and then to the finished products out of the warehouse. Especially in the assembly line, warehouse and logistics links, the precise operation of forklifts can greatly improve production efficiency and reduce labor costs.

Logistics industry: Logistics industry is one of the most widely used areas of forklift trucks. Whether it is cargo transfer at the airport, container loading and unloading at the port terminal, or cargo storage and handling at large storage facilities, forklifts are an indispensable and important tool.

Agriculture: In the field of agriculture, forklifts also show their unique application value. For example, in the storage and transportation of agricultural products, forklifts can help to quickly and accurately complete the loading, unloading and handling of goods.

Construction: Forklifts are mainly used for the handling of building materials in the construction industry. Whether it is the storage of bricks, cement, steel bars and other building materials, or the material handling in the construction process, forklifts can meet the needs of the construction industry with their strong carrying capacity and accurate operational performance.

3. Daily maintenance of forklift trucks

Cleaning and maintenance: Remove dust, oil and other debris to prevent them from entering the mechanical parts and reduce the occurrence of failures. Use a clean cloth or brush to wipe the outside surface of the forklift, especially tight joints and connections. At the same time, make sure to clean the internal parts of the forklift such as the seat, instrument panel and console.

Check the level: Forklifts use hydraulic systems to lift loads, so maintaining the correct level of hydraulic oil is critical. Check the fluid level of the hydraulic tank regularly and add or replace hydraulic oil as needed. At the same time, the hydraulic filter should also be checked and replaced to ensure the normal operation of the hydraulic system.

Tire maintenance: Forklift tires are an important part of bearing heavy loads and driving pressure. Regularly check the wear of the tires, and rotate or replace the tires as needed to ensure the stability and safety of the forklift. In addition, ensuring proper tire inflation pressure can improve the work efficiency and handling performance of the forklift.

Bearing lubrication: The bearings of forklifts are critical moving parts that require regular lubrication to reduce friction and wear. Use suitable lubricating oil or grease as recommended by the manufacturer to ensure the good running condition of the bearing.

Battery maintenance: For electric forklifts, the battery is their power source. Therefore, proper battery maintenance is essential for the normal operation of the forklift. Check the battery level regularly and add distilled water as needed.

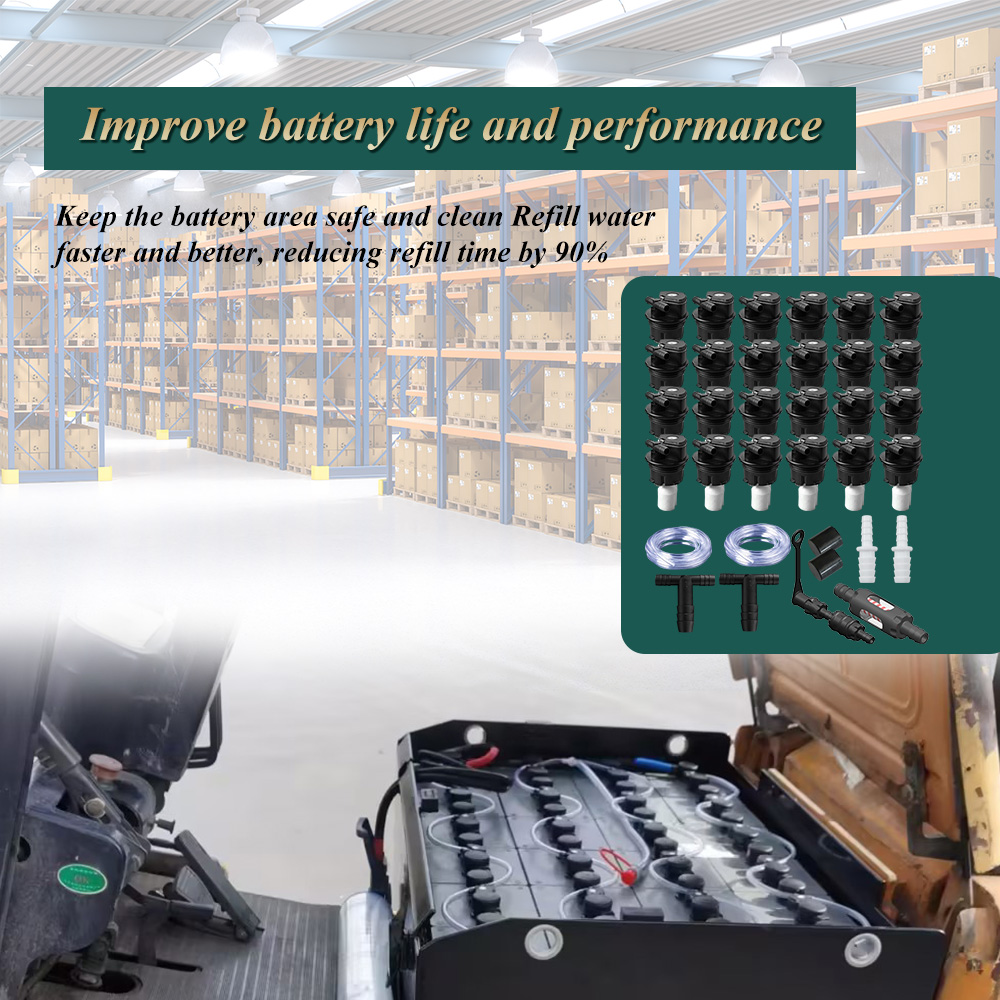

Lham Battery Automatic water refill system is an efficient battery maintenance solution. The system ensures that the moisture in the battery is kept at an optimal level by regularly replenishing the battery. The system provides an easy way to replenish water without wasting time and labor during use.

Forklift battery automatic water refill system is a kind of automatic water refill equipment developed for liquid rich battery, which can completely replace the manual water refill maintenance operation of the battery, real-time monitoring of the battery water shortage, automatic water refill, full water induction automatic stop, after installation, the electrolyte level can be kept in a healthy state throughout the whole process to ensure the stable and balanced characteristics of the battery electrolyte. Optimize the efficiency of battery equipment and extend battery life.

To sum up, forklifts play an important role in a number of industries. At the same time, in order to ensure the normal operation of the forklift and extend the service life, daily maintenance is also essential. Efficient, safe and reliable operation of the forklift can be ensured through proper cleaning and maintenance, checking the level, tire maintenance, battery maintenance and bearing lubrication.