Welcome to the website of Hubei Lham Energy Tech Co., Ltd. Our main products are automotive battery accessories and industrial battery maintenance products.

Global Consulting Hotline:0710-3313598

News

NewsLead acid battery is composed of lead dioxide positive plate, lead negative plate, microfiber diaphragm, sulfuric acid electrolyte and battery shell, pole, discharge on the positive plate of lead dioxide and sulfuric acid electrolyte reduction reaction to generate electrons lead sulfate, negative plate of spongiform lead and sulfuric acid electrolyte oxidation reaction to lead sulfate, that is, bipolar sulfate salination. When charged, it returns to its original state, with the positive electrode forming lead dioxide and the negative electrode forming lead spongy.

When lead-acid batteries are used in automobiles, conventional start-stop automobiles and micro-hybrid automobiles can be used normally because the batteries are generally used under 90% of the charged energy, according to the environmental requirements of different charging states. In medium hybrid vehicles, the battery is used at 70-90% charge, and the negative plate is easy to be sulfated; When the battery is used at 30-80% of the charged energy, the negative plate will be quickly and irreversibly sulfated, making the battery fail in advance.

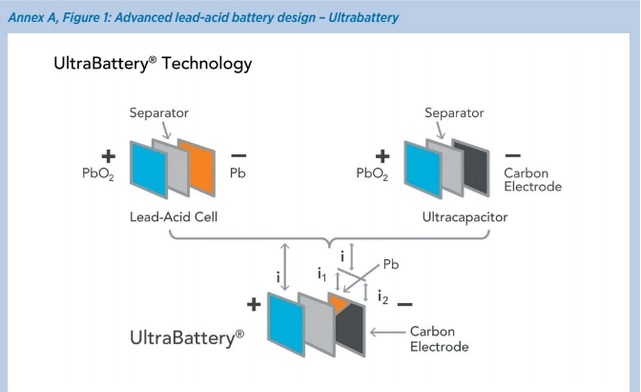

In response to this problem, L.T.L. am prepared the super battery for the first time in 2006, and modified the ordinary negative plate into half normal lead negative electrode and half carbon negative plate. By connecting the ordinary negative plate to the supercapacitor in parallel, the sulfation of the lead negative maximum current can be alleviated. However, due to the potential difference between the two kinds of negative electrode, the capacitor potential is more negative, and the negative electrode is serious hydrogen evolution. In order to solve the hydrogen evolution and two kinds of negative electrode assembly cumbersome problems. The negative plate is made by directly mixing carbon material with spongy lead. The production method is similar to that of traditional lead-acid battery, which has better battery performance and operability, namely lead-carbon battery.

Lead carbon battery can extend the cycle life of hybrid electric vehicles under high rate partial charge (HR-PSOC) operation. Lead carbon batteries and related technological innovations are as follows:

1. Plate grid, plate grid plays the role of conducting current and supporting active substances, usually plate grid is lead calcium tin aluminum alloy, in order to slow the positive plate grid corrosion caused by battery failure. First, the grid can be surface-treated by aniline immersion to reduce the physical impedance. Secondly, graphene can be added. Graphene and metal lead have fine and uniform grains and dense arrangement, which can effectively reduce the corrosion of grid. At the same time, during the REDOX reaction, the grain resistance formed by metal lead and graphene is much smaller than that of pure metal lead, so the current density is also greatly improved. In addition, graphene can increase grid hardness, shorten grid hardening time, reduce inventory cycle, improve capital turnover, and effectively reduce production costs;

2. Positive plate, positive active material is 70-88% oxidation degree Barton lead powder and ball ground lead powder. Hu et al. synthesized nanostructured lead oxide containing porous carbon skeleton and mixed it with ball milling lead powder, which could increase the utilization rate of positive active substance to 72.5%. Due to the complex structural transformation of lead dioxide, additives are easy to have a negative effect on it. Graphene porous carbon can be added to accelerate positive plate formation, reduce interface impedance, increase the crystal gap of the reaction product lead sulfate, improve charge transfer efficiency, control the size of lead sulfate crystal, so as to avoid negative sulfation and extend battery life. Lang et al. added 4%4BS (nano 4 basic sulfate) to the positive electrode to obviously improve the battery cycle life, and the application effect is obvious.

3. Negative plate, negative plate is the key to lead carbon battery, to have the characteristics of both battery and capacitor. Therefore, a certain proportion of carbon material with electrochemical activity should be added to the negative electrode to enable capacitance buffering and depolarization. Conventional additives include: sulfonated lignin and humic acid organic expansion agents, conductive carbon, barium sulfate and staple fiber, etc. It mainly plays the role of increasing the active material capacity of negative plate, slowing down sulfation, improving structural stability and enhancing the charging ratio of negative plate. The negative plate of lead carbon battery is to add a higher proportion of capacitive carbon materials, such as carbon nanotubes and graphene oxide materials, to the conventional lead paste, at the same time add dispersant for the dispersion of carbon materials with high specific surface, indium oxide and other additives to inhibit hydrogen evolution caused by carbon materials, and enhance the binder PTFE that causes low strength of negative plate after carbon addition. In order to prevent negative plate oxidation, the curing time can be extended and the internalization process can be adopted.

4. Electrolyte, electrolyte is dilute sulfuric acid solution, participate in the battery reaction, charging concentration increases, discharge concentration decreases, and the charging process accompanied by hydrogen evolution reaction, with the reduction of water, concentration will increase, affecting the battery performance. The additives in the electrolyte mainly include sodium salt and potassium salt to improve the electrical conductivity, and phosphoric acid to slow the shedding of positive active substances. And high hydrogen evolution overpotential metals and their compounds or ionic liquids used to inhibit hydrogen precipitation. Zhao et al. took 240mg/L cetyltrimethylammonium bromide and 20mg/L benzylacetone as electrolyte additives to significantly improve the cycle life and conclude that it can inhibit hydrogen evolution.

5. Electrical performance: compared with lead-acid batteries, lead-carbon batteries increase charging speed by 8 times, discharge power by 3 times and cycle life by 6 times. Compared with the energy density of lead acid battery 20-40Wh/kg, lead carbon battery can be improved to 40~60Wh/kg, the cost performance has been greatly improved.

As an innovative technology of lead-acid battery, lead-carbon battery not only expands its application in the field of medium and hybrid all-hybrid vehicles, but also further reflects its value in the field of large-scale and super-large-scale energy storage.