欢迎您访问湖北联鸿能源科技有限公司网站,我司主营汽车蓄电池配件、工业蓄电池维护保养产品

全国咨询热线:0710-3313598

Technology

TechnologyWith the advent of severe winter, due to the low temperature in winter, it is very difficult for internal combustion forklifts and electric forklifts to start, which will affect work efficiency. For forklifts, the test brought by low temperature, rain and snow in winter is more severe than usual! If the internal combustion forklift and electric forklift are used incorrectly at this time, it will directly affect the starting effect and even damage the forklift accessories. So, how to maintain the forklift in a batter way in winter?

Today, I specially compiled some knowledge about forklift maintenance in winter. Take it away quickly. You’re welcome!

How to maintain electric forklift?

一.Internal combustion forklift maintenance

(1).Diesel

At low temperatures, the increase of the viscosity of the diesel for internal combustion engine forklifts makes its fluidity, atomization, and combustion worse, and the startability, power and economy of the internal combustion engine forklift diesel engines are significantly reduced.

Therefore, diesel, pallet trucks and tank trucks with low suspicion should be selected, that is the freezing point of the selected diesel is generally 3-5C lower than the ambient temperature to ensure that it will not affect the use due to solidification at the lowest temperature.

Generally speaking, 0# diesel can be used in the south of the Yangtze River in winter, -35 diesel in severe winter in northeast, northwest and border areas, and -20 diesel in severe winter in other regions.

(2)Engine oil

At low temperatures, the oil viscosity of internal combustion forklifts increases as the temperature decreases, fluidity becomes worse, and frictional resistance increases, these make it difficult for the diesel engines of internal combustion forklifts to start. Therefore, the lower viscosity oil should be replaced in time,and if the oil has stronger fluidity, this can lubricate the internal precision parts of the internal combustion forklift engine.

(3)Forklift gear oil and grease

The original gear oil should be replaced in winter to lubricate the deceleration and transmission system of the internal combustion forklift. The hinge mechanism and wheel hub bearings should be filled with low-temperature grease for better lubrication.

(4)Hydraulic oil

The hydraulic oil of the internal combustion forklift should be replaced according to the working environment of the forklift. The ISO VG46 hydraulic oil should be replaced when the forklift is working or parked for a long time below -20. When the vehicle is used above -20, ISO VG32 hydraulic oil should be used.

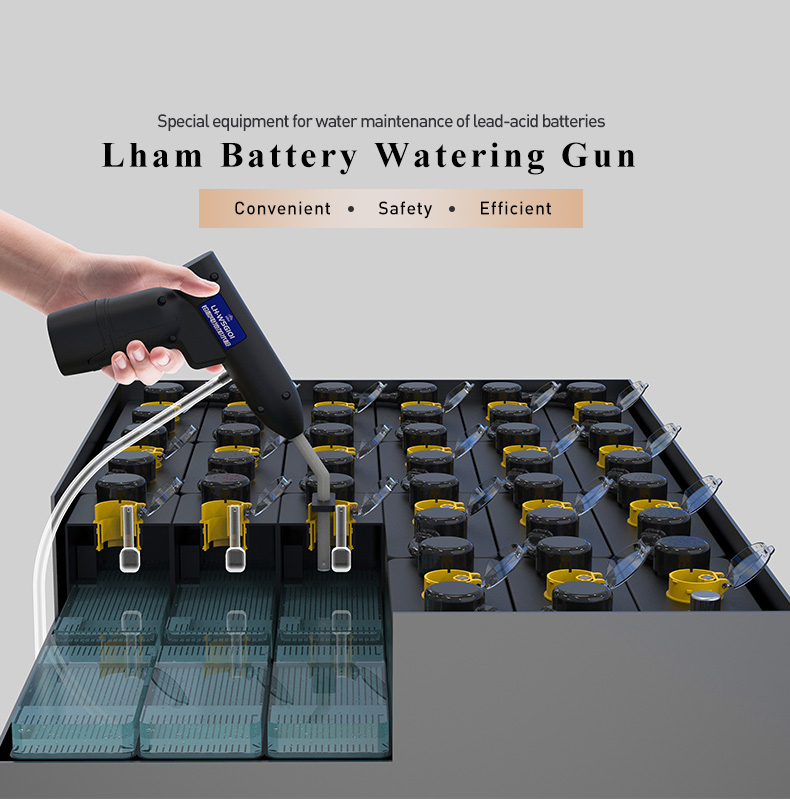

How to maintain electric forklift? You can use lead-acid battery watering gun.

(5)Check and replace forklift brake fluid

Check the brake fluid of the internal combustion forklift. If it is dirty, badly deteriorated, or mixed with water, replace the original brake fluid in time.

(6)Replacement and inspection of forklift cooling system.

Check to ensure that the cooling water in the fuel tank of the internal combustion forklift is antifreeze in winter to prevent the forklift from being parked at low temperature for a long time and the cooling system cannot work normally. Check to make sure the thermostat and water pump are working.

二.Use and maintenance of electric forklift batteries.

(1) When the weather temperature is lower than 10, it is best to bring the electric forklift and battery to indoors to charge or park. Avoid charging the electric forklift outdoors overnight or charging in a low temperature environment to ensure that the battery can be fully charged.

How to maintain electric forklift?

(2) Use the battery after the battery is fully charged every day. However, the high-current charging time is not allowed to be too long, otherwise the battery of the electric forklift will be overcharged, which will affect the service life of the battery.

How to prolong forklift Lead-acid battery service life? Battery watering gun is your best choice. Check the following detailed information

How to fill water for lead-acid battery? We suggest you use battery watering gun.