欢迎您访问湖北联鸿能源科技有限公司网站,我司主营汽车蓄电池配件、工业蓄电池维护保养产品

全国咨询热线:0710-3313598

Technology

TechnologyThe same batch of batteries produced, it is impossible for the voltage of each battery to be absolutely consistent, as long as a little "difference", in the process of charging and discharging, the "difference" is getting larger and larger, and finally the charge of high voltage is excessive, resulting in the decomposition of internal water and gas, and the low voltage is insufficient to charge, and the internal vulcanization is produced. Causing the battery to die prematurely. In order to overcome the "difference" enlargement. In the production of batteries, there must be a "combination" process, and the batteries with small capacity differences are placed in a group. Although this process takes time and labor, it cannot completely solve the problem, but it only delays the time for the expansion of the "difference".

According to relevant authoritative information, the "difference" within 3% has little impact on the life of the battery. A 3% difference for a 12V battery is 360mV. The same batch of batteries produced, paste composition, process operation are the same, so the "difference" is very small. After using the equalizer, the "difference" will no longer expand, and the manufacturer can eliminate the "matching" process. It not only reduces costs but also extends battery life.

Each battery is connected to an equalizer, and the battery voltage gradually increases when it is charged. Once the voltage reaches the "floating charge" potential, the equalizer switches on and starts diverting, thereby reducing the battery's charging current.

It can be imagined that the earliest charging voltage reaches the "floating charge" potential, so the charge is less. The low-voltage battery reaches the "floating charge" potential later, the charge is more, and the battery gradually reaches equilibrium after several charges and discharges. Although this equalizer is simple and practical, it also has unsatisfactory shortcomings, when the battery is charged to the "floating charge" potential, the charge is near the end, and the equalizer begins to work at this time, and the balancing effect is limited. In order to improve its balancing effect, only increase its shunt current, but the heat is also increased. Therefore, a new equalizer idea is proposed, which is to compare a group of battery voltages in series with each other. If the voltage is high, shunt is performed. The low voltage is not shunt, and the entire charging process has a balancing effect, so the shunt current is very small.

When our company studies the balancing technology, comprehensively considering the user's operation and maintenance costs and battery usage habits, Lianhong has devoted itself to the development of an active balancing system for many years, which solves the problem of charge and discharge balance of battery packs such as electric forklifts, electric vehicles, and electric tractors, effectively extending the battery range and the service life of battery packs.

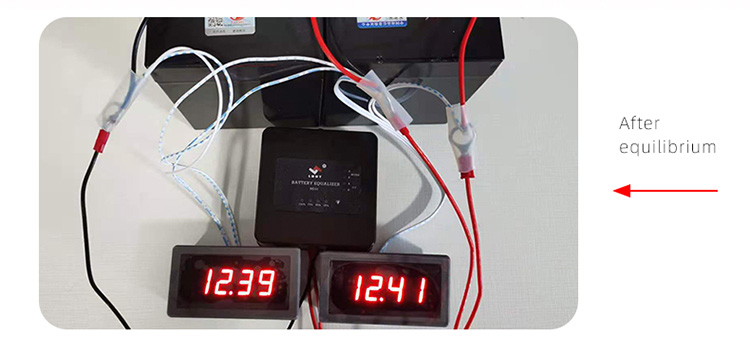

The battery equalizer itself is a typical current and voltage balancing device. When charging, the equalizer is through the detection of voltage, found the pressure difference through the mutual energy transfer of current and voltage compensation. To achieve the balance of the battery voltage convergence, to prevent the overcharge and undercharge of the battery! The battery equalizer plays a good protective role on the battery and can extend the service life of the battery.

Lham Battery Equalizer is an active balancing system developed for many years, which solves the problem of charge and discharge balance of electric forklifts, electric vehicles, electric tractors and other battery packs, effectively extending the battery range and battery life.